F. Ball delivers Showroom Finish

Fitters from flooring retailer Carpets R Us, in Taunton, used F. Ball and Co.’s Stopgap 1600 fast-drying, fibre-reinforced smoothing compound to encapsulate retrofitted water-fed underfloor heating boards as part of a textbook flooring installation in their own showroom.

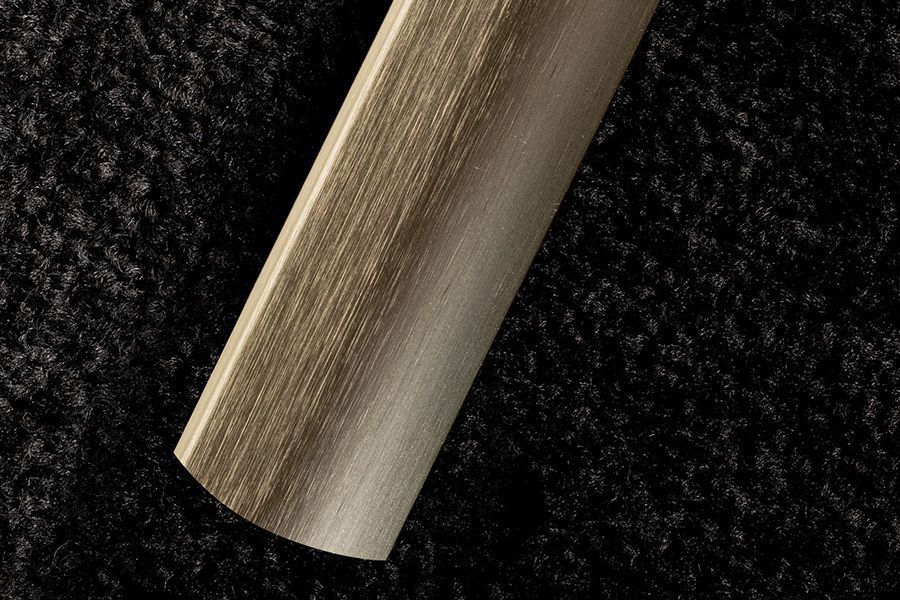

After applying F. Ball’s Stopgap P131 primer over the system to promote the application characteristics of the smoothing compound, Stopgap 1600 was applied over the 90m2 cement board system affixed to the concrete subfloor.

The product is formulated especially for use over underfloor heating systems and can be applied between 3 - 40mm thick to encapsulate electrical wired or water-fed systems installed over internal subfloors as part of new build or refurbishment projects in both domestic and commercial environments. It is suitable for use over a wide range of absorbent and non-absorbent subfloors, walk-on hard from three hours after application and ready to receive floorcoverings in as little as 12 hours.

F. Ball technical service officers recommend allowing 5-35mm of a smoothing compound above retrofit electrical wired or water-fed underfloor heating systems, depending on the type of system being installed (less for electrical wired systems) and the manufacturer’s instructions.

Once the smoothing compound had dried, fitters again primed the surface with Stopgap P131 primer before capping with a layer of F. Ball’s Stopgap 1200 high-performance smoothing compound, which is walk-on hard in as little as 60 minutes after application and ready to receive floorcoverings from four hours.

The showroom installation was completed with the installation of Gradus carpet tiles and Moduleo LVTs, showcasing the standard of workmanship that Carpets R Us customers can expect in their own homes.

Henry Griffin, Carpets R Us, said: “As well as using F. Ball yellow bucket adhesives, we exclusively use F. Ball smoothing compounds. This was the first time we’ve used Stopgap 1600 over a cement board water-fed underfloor heating system, and it is the perfect product for the job. We’re grateful to F. Ball’s Technical Service Department for advising on subfloor preparation, including priming and the minimum thickness of smoothing compound. This meant that everything went smoothly.”

www.f-ball.com