“Make the switch to XPS Foam Underlay” - A Chat with Kathryn McHugh, Ops Director at XPS Foam Ltd

Kathryn McHugh, Head of Operations at XPS Foam Ltd — the UK’s only manufacturer of XPS Underlay — shares why more flooring fitters are making the switch to XPS Foam Underlay.

Q: Kathryn, what exactly is XPS foam and what makes it different from other underlays?

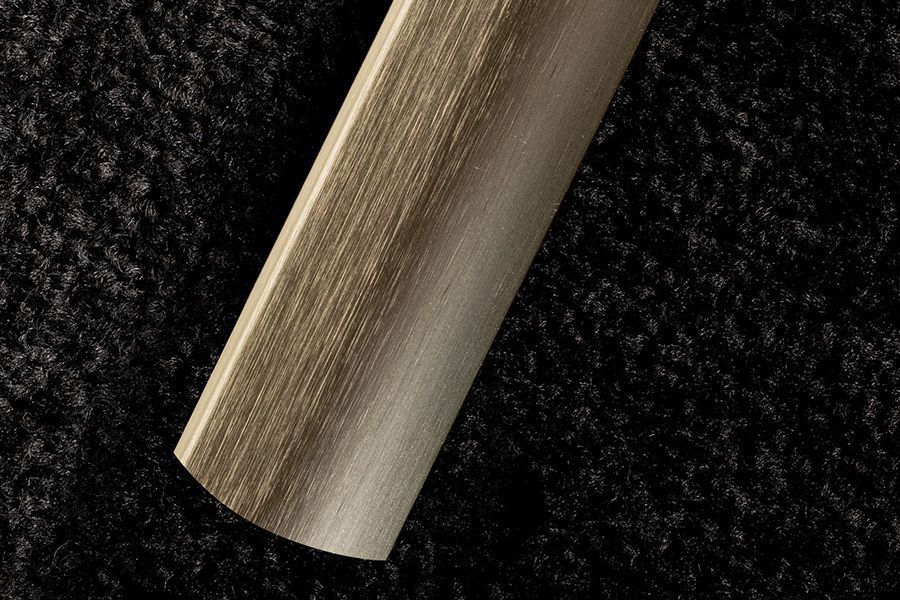

Kathryn: XPS stands for extruded polystyrene. It’s stable, lightweight board that doesn’t compress or deteriorate over time. Compared to traditional underlays like fibreboard, XPS provides enhanced performance for thermal insulation, moisture protection and sound absorption. It’s incredibly easy to work with — which we know is a top priority for fitters trying to get jobs done quickly and cleanly.

Q: You mentioned moisture resistance — how important is that for installers?

Kathryn: XPS doesn’t absorb moisture, doesn’t rot and won’t support mould growth. That makes it perfect for lower ground or older buildings where damp is a concern. Our foil-backed PLUS Underlays have integrated vapour barriers, so there’s no need for an extra membrane.

Q: Sounds like there’s a strong thermal benefit too. Is that something fitters are actively looking for now?

Kathryn: Definitely. Energy efficiency is a big selling point with homeowners. XPS helps retain heat by reflecting it back into the room, especially useful over cold concrete or with underfloor heating systems. Fitters tell us their customers notice the difference — floors feel warmer and more comfortable.

Q: What about noise? Is that something XPS helps with too?

Kathryn: Absolutely. XPS underlays help reduce noise from impact and footfall, which is particularly important in flats or upstairs rooms and at the same time, gives the floor a more solid, cushioned feel.

Q: From a fitter’s point of view, how easy is it to install?

Kathryn: The boards are lightweight and easy to cut. Our foil-backed PLUS Underlays have overlap tape already applied, which means faster installs. We’ve designed everything to be efficient — lay it, fit it, and move on.

Q: You’re the only UK manufacturer of XPS underlay — what does that mean for the trade?

Kathryn: It means better service, faster lead times, and consistent quality. We manufacture over 10 million square metres annually and work with national retailers and distributors, so our products are ready when fitters need them. Plus, by producing everything in North Wales, we’re supporting local jobs and reducing the environmental impact of long-distance imports.

Q: Speaking of the environment, what’s the sustainability story with XPS?

Kathryn: Our underlays are made from up to 100% recycled plastics and can be recycled again at the end of their life. So not only do fitters get a high-performance product — they’re making a greener choice too.

Q: Finally — what would you say to a fitter who’s never used XPS before?

Kathryn: Try it on your next job, you’ll see how much easier it makes things. There’s no dust, it’s quick to lay and built to last. Whether you’re fitting laminate, engineered wood, LVT or click vinyl, we’ve got a solution that fits the job — and we made it specifically for the trade.