Vinyl tiles

As manufacturing technology continues to develop, the ability of LVT to accurately mimic any natural surface becomes even more impressive. Bypassing the often high costs associated with their real-life counterparts, wood- and stone-effect LVT ranges offer customers a variety of aesthetic options unmatched by almost any other type of flooring.

Matching the versatility of their designs, these tiles can be offered in a huge array of formats, from the popular herringbone to the classic plank, also enabling installations to be carefully planned down to the tile to reduce waste. Of course, the durability and easy maintenance of LVT remains one of its most important features, allowing it to maintain that chosen aesthetic over its entire lifetime, even in higher traffic areas of the home.

For all of these reasons and more, LVT has become one of the most sought-after floorcoverings for areas like kitchens and hallways, and its popularity only seems likely to grow from here! Below, we’ve collated a few of this year’s top LVT ranges as well as some advice on ensuring optimum results at the installation stage.

Elevate your space with the timeless flooring elegance of ALVA

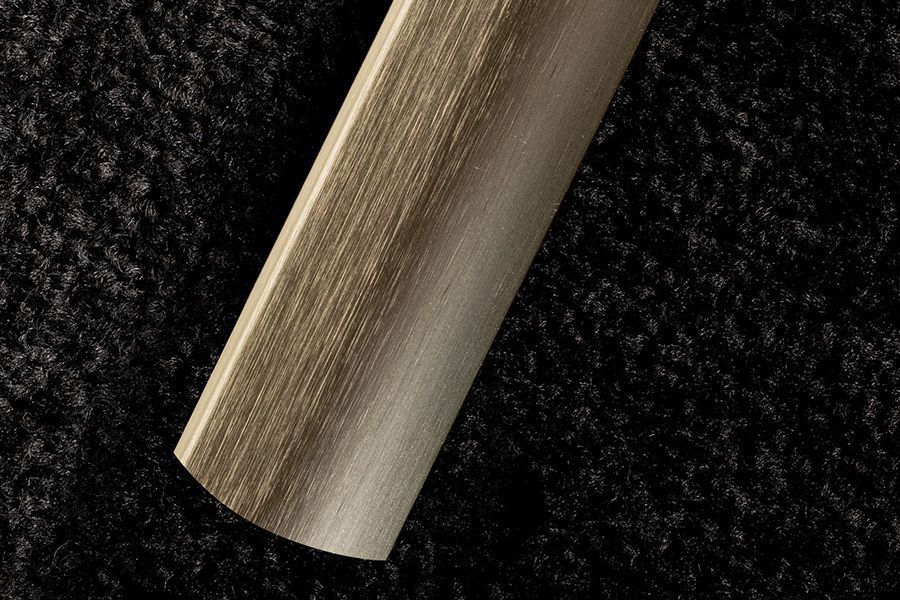

Discover the perfect balance of style and functionality with the ALVA flooring collection. Whether you’re drawn to the moody sophistication of wide plank designs or the classic charm of elegant herringbone, each option adds unique character to your home.

Available in herringbone, plank, and tile formats across 22 outstanding colours, ALVA offers versatile design choices to suit any style.

Crafted for durability and designed to impress, ALVA floors are more than just a foundation — they’re a statement. Perfect for modern living rooms, kitchens, and open-plan interiors, our styles enhance any space with texture, warmth, and depth.

With easy maintenance, eco-conscious materials, and long-lasting performance, your new floor offers more than beauty — it’s built to endure everyday life with ease.

It’s time to create your space.

www.kellars.co.uk

Karndean offers onyx-effects in LVT

Stone-effect LVT flooring continues to evolve, moving beyond classic limestones and marbles to explore more daring and decorative designs. For those looking to make a design statement, the new onyx designs from the recently updated Art Select collection by Karndean Designflooring offer a captivating alternative. Inspired by the translucent beauty of the semi-precious stone, this trio – Pearl Onyx, Rose Onyx, and Black Onyx – brings a luxurious edge to contemporary interiors.

With their swirling veining and soft, layered colouring, these unique stones introduce depth, drama and elegance to any space without compromising on practicality. Traditionally too delicate and rare for everyday use, onyx has been reimagined by Karndean’s design team as a practical, easy-care flooring that works beautifully in modern homes.

Gavin Smith, Marketing Director at Karndean Designflooring, said: “Onyx is a stone we’ve long admired for its natural glamour, but it’s not a practical option in its raw form. By recreating it in LVT, we’ve captured that sense of luxury in a format that’s accessible, durable and ideal for everyday life.”

Guaranteeing optimum results

Given the premium associated with LVT and customers’ high expectations for finished results, it is useful to know how to ensure a flawless finish when installing them. Neil Sanders, technical director at the UK’s leading manufacturer of subfloor preparation products and adhesives for floor coverings, F. Ball and Co. Ltd., talks through what is involved.

A long-lasting, visually attractive flooring finish when installing luxury vinyl tiles or planks involves following the basic principles of subfloor preparation, as well as taking precautions to avoid common causes of floor failure. This can be broken down into a few simple steps. Careful product selection at each stage of the process will also help optimise the installation.

Creating a base

F. Ball recommends that a smoothing compound is applied over the subfloor to create a perfectly smooth base for the receipt of floor coverings and ensure that the visual appearance of an installation is not compromised by imperfections in the subfloor showing through.

Before you apply a smoothing compound, the first step in any flooring installation should be to check that the subfloor is suitably sound, smooth and dry. Any laitance and contaminants should be mechanically removed.

At this stage, a moisture test should be conducted to determine if the subfloor is dry enough to receive floor coverings. Where Relative Humidity (RH) levels are higher than 75%, a moisture management solution will be required to prevent moisture attacking flooring adhesives and causing resilient floor coverings to blister and lift, potentially ruining the appearance of the installation. The usual solution for suppressing excess subfloor moisture is the application of a liquid waterproof surface membrane.

Prime importance

You also need to prime the subfloor. Primers promote adhesion between the subfloor and the smoothing compound applied over it. Applied over absorbent subfloors, they also stop the unacceptably rapid drying of smoothing compounds, which can result in insufficient strength build up and a reduction in the open time or wet edge of the smoothing compound.

Another benefit of priming is reducing ‘pinholing’: small holes in the smoothing compound that have the appearance of pinholes or blisters caused by the slow escape of air from absorbent surfaces as the smoothing compound cures.

Adhesive selection

To adhere the LVTs to the smoothing compound, pressure sensitive adhesives, such as F. Ball’s Styccobond F46, are usually the best choice. They form an instant grab upon contact, so installers don’t need to worry about tiles or planks sliding about when they are working, making them ideal for installations with intricate designs or patterns.

Styccobond F46 is part of F. Ball’s System LVT range, which comprises waterproof surface membranes, primers, smoothing compounds and adhesives that used correctly and in combination F. Ball guarantees will result in an aesthetically pleasing floor finish that lasts the lifetime of the installation.

The range also features pressure sensitive adhesives with a variety of other specialist attributes, including moisture tolerance and the ability to hold vinyl floor coverings firmly in place in areas exposed to extreme temperature fluctuations (from -20°C to +60°C).

Compatibility check

Finally, it is highly recommended that contractors always check the compatibility of particular floor coverings and adhesives. To do this, you can consult the floor covering manufacturer’s guidelines. Alternatively, F. Ball produces a Recommended Adhesives Guide (RAG), which lists adhesives recommended for use with over 6,000 floor coverings produced by over 200 manufacturers. The guide is available as a free app or a printed booklet. An interactive version can also be found on the F. Ball website. Alternatively, contractors can contact F. Ball’s technical service department, from 8.30am–5.00pm, Monday to Friday, for advice on adhesive compatibility.

www.f-ball.com